New Technological Horizon: Clayens, a Pioneer in Anti-Friction and Anti-Sticking Through Micro and Nanotexturing of Tooling

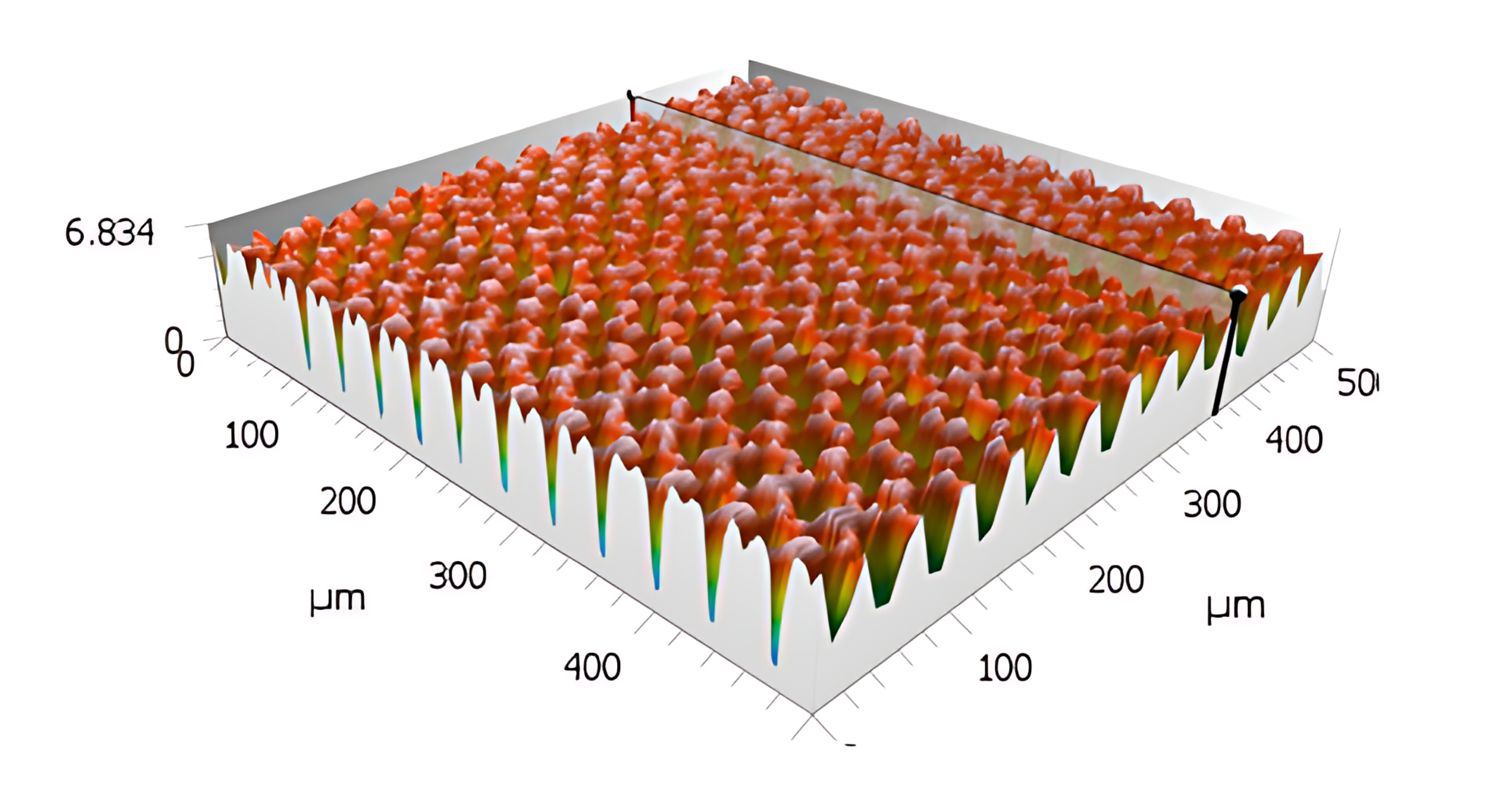

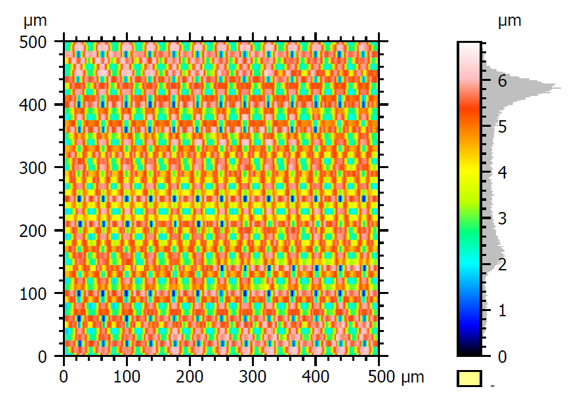

Clayens Group is at the forefront of innovation in the field of surface texturing for plastic parts. The principle of this technology lies in the creation of micro and nano textures on injection tooling. These extremely precise patterns, once replicated on plastic parts, radically alter their behavior by endowing them with unique properties: by adjusting the surface topography at a micro/nanoscale, it's possible to transform their functional properties, thus opening a wide and revolutionary field of applications in many sectors, especially in medical devices.

Following spectacular results in improving the flow properties of textured parts, Clayens' R&D teams have focused on anti-sticking and anti-friction problems. While anti-sticking aims to prevent the adhesion of surfaces (especially between materials of different rigidities), anti-friction focuses on reducing resistance to movement between two surfaces.

Two concrete examples illustrate the effectiveness of this technology in solving specific problems:

In the field of drug administration devices, a major challenge was overcome: reducing friction between polypropylene (PP) and polyethylene (PE), which made activating the device too difficult. Thanks to Clayens' micro/nanotexturing, the force required to activate the device was reduced by 30%, thus facilitating its use.

In another case, involving a drug reconstitution device, the problem lay in the interaction between soft TPE and rigid PC, where unwanted adhesion increased the activation torque. The application of our technology enabled a significant reduction of this torque by more than 50%. This innovation not only solved the sticking problem but also led to the elimination of lubricants, reducing contamination risks and simplifying regulatory compliance.

It's essential to underline that, in both cases, the parts treated with our technology are in direct contact with the drug. This critical proximity required adding advanced functionalities to the components without altering the composition or properties of the initially chosen material.

"Each step forward in our work with texturing technology brings its share of surprises and results that often exceed our expectations. It's incredible to see how each advancement opens up new perspectives. The applications seem endless, offering innovative and effective solutions for a multitude of industrial challenges," explains Pauline SPARD, from the Health R&D department of CLAYENS.

This technology transcends the traditional limits of materials engineering, offering benefits well beyond just flow, anti-friction, and anti-sticking applications. Its ability to reinvent the properties of plastic parts opens doors to revolutionary applications in various sectors, including but not exclusively in the health field.

Stay tuned: In the coming months, we plan to publish an article on our ongoing work related to the antibacterial properties of textured parts!

To learn more about our innovations and services, contact us!

About Clayens

CLAYENS Healthcare represents the Healthcare activity of Clayens Group and supports healthcare industry players (medical devices, pharmaceuticals, and diagnostics) in the development, industrialization, and manufacturing of custom-made medical devices and plastic components in compliance with international regulatory standards.

CLAYENS Healthcare offers a comprehensive service from R&D to production, including industrialization, qualification, validation, and regulatory support. With a presence in 9 countries, Clayens Group has nearly 5,100 employees and 32 manufacturing sites. The Group's Healthcare plants and cleanrooms (ISO7 and ISO8) are located in Europe and North America (France, Mexico, USA).

For more information, please visit: https://www.clayens.com/healthcare