Clayens : Meeting on additive manufacturing

The synergy between Clayens' various production sites is helping to develop additive manufacturing within the group. On 26 September, an internal meeting will take place. Participants will have the opportunity to explore this topic further. The meeting will bring together more than 25 representatives from the majority of the EMEA plants. The aim is to collaborate, exchange ideas and enrich the global knowledge of professional practices on the subject, thanks to their complementary skills.

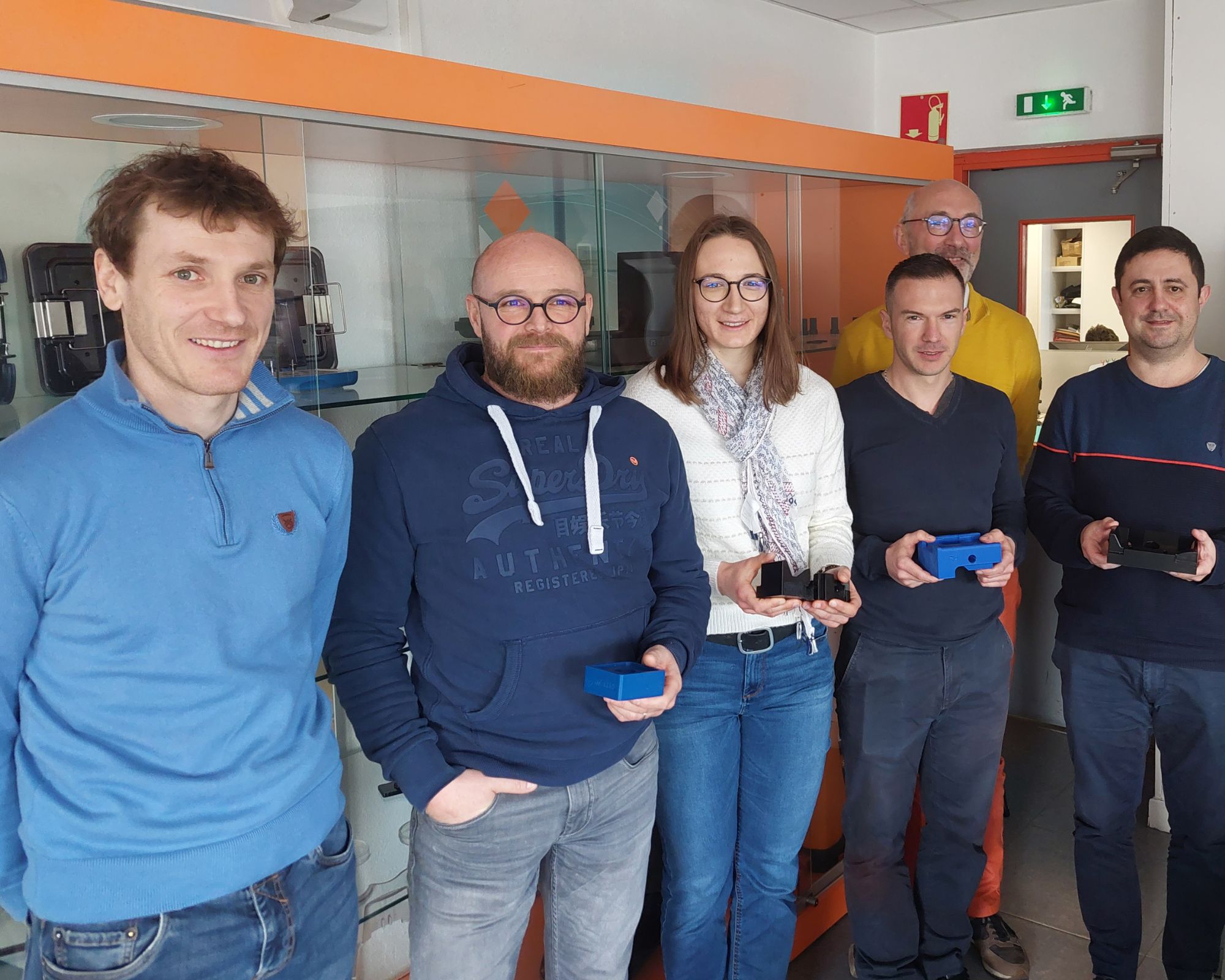

Orchestrated by Matthieu Besse, Team FA 3D Group Leader and Health R&D Manager at Clayens NP Plastibell, site representatives will have the opportunity to share their experiences, thoughts, knowledge and expertise. Collaborative working groups will stimulate exchanges and interactions, particularly on the future perspectives of FA within Clayens. A visit to the Fab Lab POLYVIA, which has been transformed into a demonstration facility for the occasion, will provide concrete examples.

Jérémy Haw, founder and CEO of the start-up G28 Ready-To-Print, which specialises in sharing expertise in 3D printing, and more specifically in FDM technology, will be present as a consultant and will contribute his knowledge and experience to the discussion.

About :

For more than 2 years, the Team FA 3D team has been working on the development of additive manufacturing at Clayens.

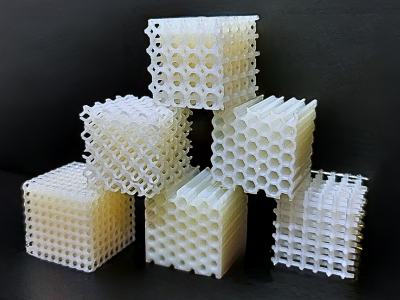

Additive manufacturing, also known as 3D printing, works by adding thin layers of material to form various parts, even the most complex ones. This technology has revolutionized the way we design objects. All you need to do before printing is to create the desired part in 3D using software. There's no need for tooling, because additive manufacturing can be adapted to suit different projects and needs.

Today, the parts manufactured are mainly used internally on various projects (for the production and inspection of molded parts, for example). The advantages of developing additive manufacturing are multiple: reducing material waste, optimising manufacturing times, gaining greater autonomy within the group itself, but also producing more complex parts thanks to the customisation and freedom of design offered by this technology.