Given our industrial background on a wide range of industries applications (Automotive, Healthcare, Aeronautic, Electronics) and given our complex machine inventory, we aim to be at the cutting edge ot the technology as we get involved in product or process innovation, both through either partnership or with our clients from idea to industrialization.

On top of that, we know that finding the best cost/performances/quality optimisation can be such a challenge. We tend to achieve it without compromising the project reactivity or innovation.

Research and development

From idea to realisation

- Technical Pre-Study

- Material and Process identification

- Economic study

- Specification

- Product Design

- Tool Design

- Prototyping and Representative scale production

- Mechanical and Chemicophysical characterisation

- Production

- Industrial representative process

- Quality process development

- Qualification Test Plan

- Automation

Composite / Hybride - Plastronique /

Smart Plastics - Santé / Medical Devices

Composite / Hybride

From material selection to process industrialisation

CLAYENS is working on many different process, which go from composite processing to finishing

• Thermoplastic (TP) Molding CFRP, TP Hybrid (Stamping/Overmolding), Metalic/Composite TP Overmolding & Thermoset (TS) Compression

• Monitoring, Surface Functionalization, Insert Overmolding, …

From low to high performances :

• PEEK/PEKK/LMPAEK/PEI/PPS/PA/PP/PC & SMC (Epoxy/Polyester) …

• Short and long fiber reinforcement, Glass and Carbon

Our long history in processing and design of polymer application provide us with a good understanding of the different key parameters that can make a composite application a real game changer, either in term of mass reduction, functionalization or recyclability.

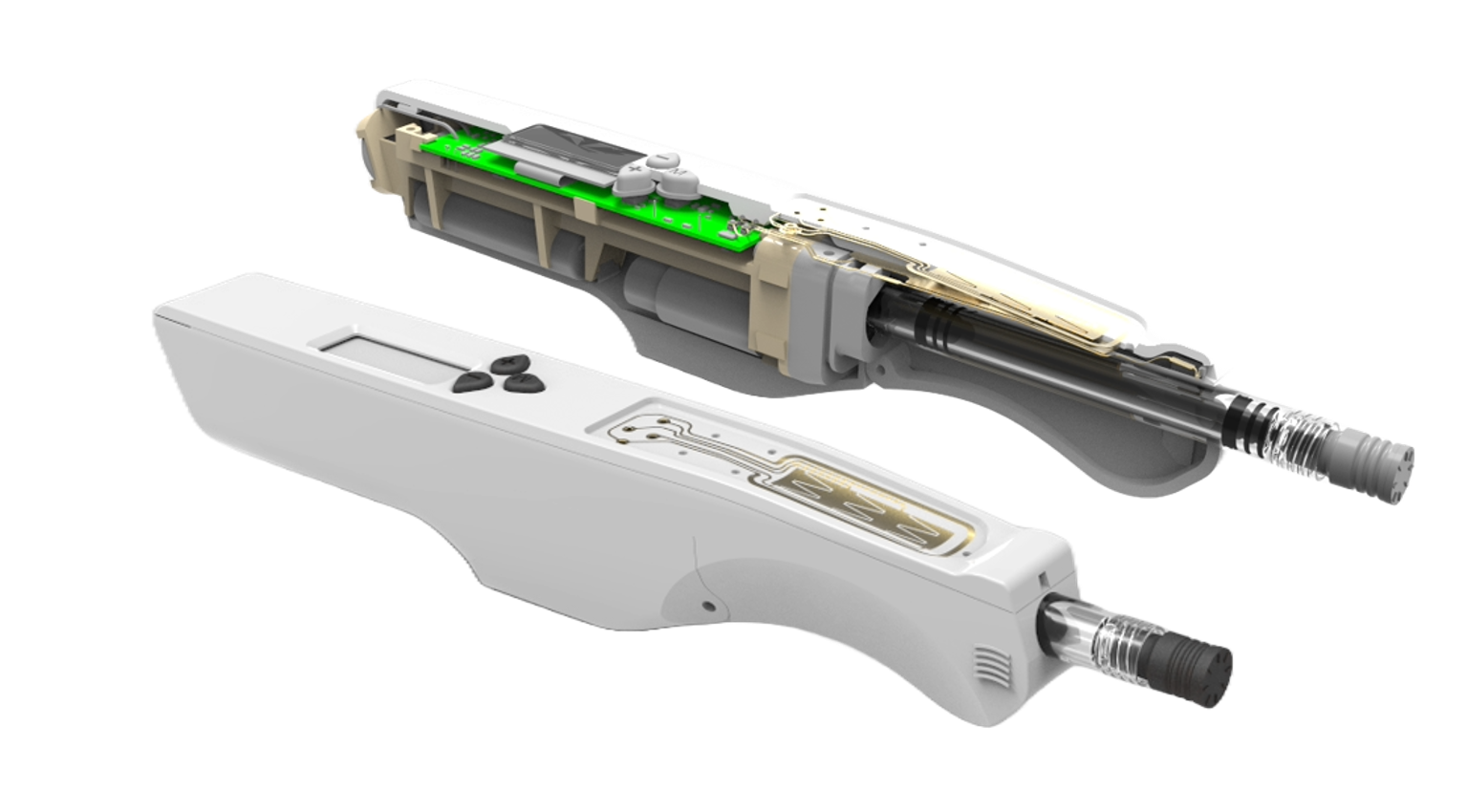

Electronics / Smart Plastics

A Multiprocess leader

Thanks to its knowledges in both polymer processing and electronics, CLAYENS is a key player in the field of smart plastics, sometime called plastronics.

From design of a product, up to series manufacturing, CLAYENS offers – directly or via strategic partnerships – a full range of processes (LDS, 2K-molding, deshunting, PowerMID®, …), allowing an optimized answer to any need: technical parts, high power, high aspect parts, …

For many years CLAYENS is a major player in the development of the IME process (In Mold Electronic). As a matter of fact, it manages in house all the steps of the process (printing, chips dispensing, thermoforming and overmolding). Partnering with industrial leaders (automotive, electricity / electronics, aeronautics, household devices, …), and also university labs, CLAYENS has developed a broad range of applications, such as: 3D Human / Machine Interfaces (HMI), sensors at the closest of the event, deicing of leds lighting, …

CLAYENS partners with TACTOTEK, IMSE® technology leader, is a member of the AFELIM (Association Française de l’ELectronique IMprimée) and is patron of the Fundation of the Lyon University of the course « project manager in plastronics”

Healthcare

A single information point with unique and wide expertise

Meeting the challenges of tomorrow's health requires the search for innovative ideas: our R&D teams are constantly evaluating, with our customers, in partnership or independently, innovative technologies and industrial processes that could open up new perspectives in the field of Healthcare (connectivity, functionalization of surfaces, materials, sterile barriers, asepsis, cleanliness, etc.).

In addition to technological innovation, we emphasize also the product innovation: user-centered co-design. It is accompanied by means allowing the production of small series (ISO7 Pilot Line) and the validation of the performances (Health Lab) of new products. This approach is inspired by trends in each health sector in which our customers' products are positioned (pharmaceutical packaging, in vitro diagnostics, medical devices and equipment, etc.). It anticipates needs and ensures compatibility with the industrial reality of our activity.